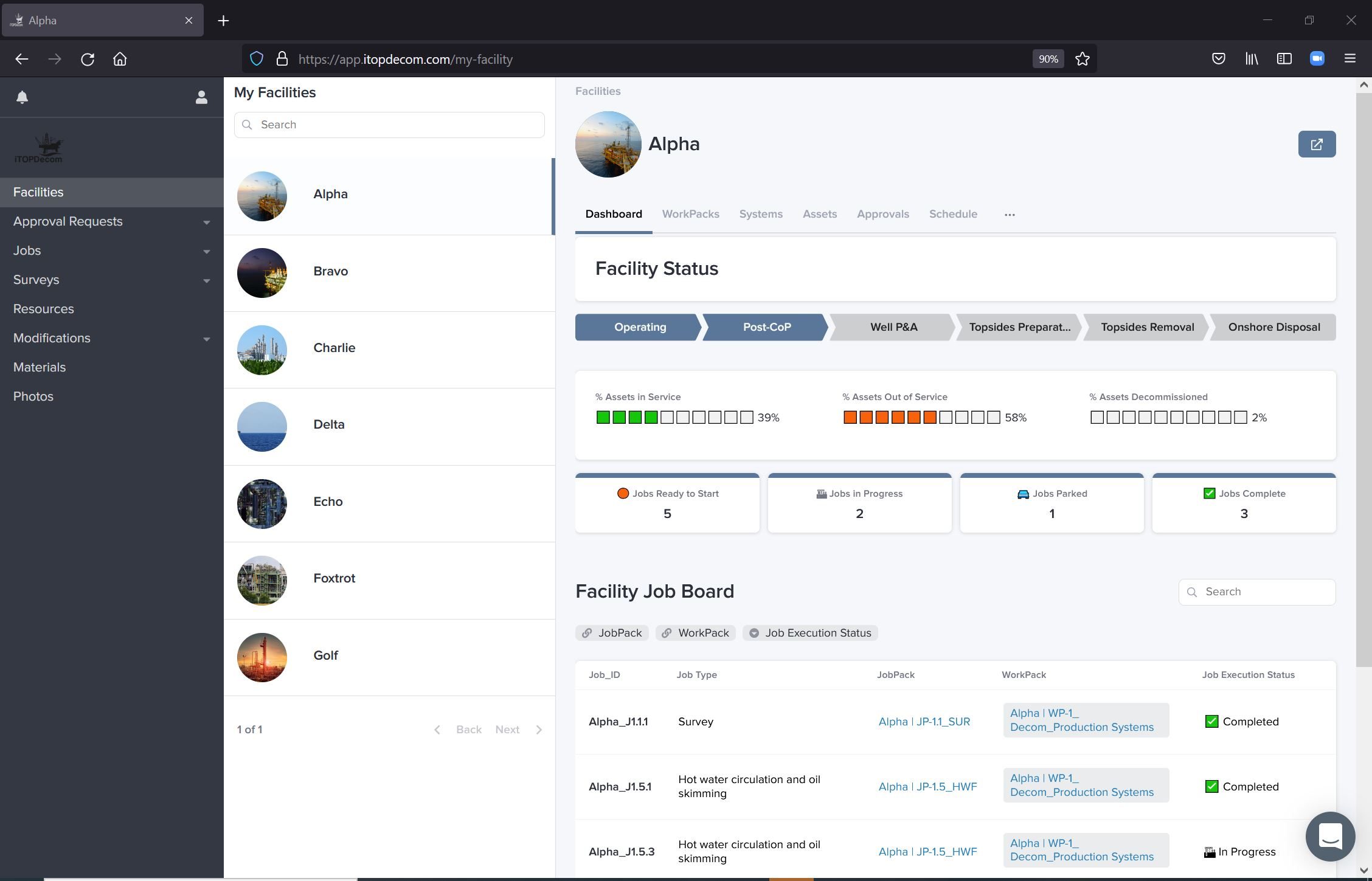

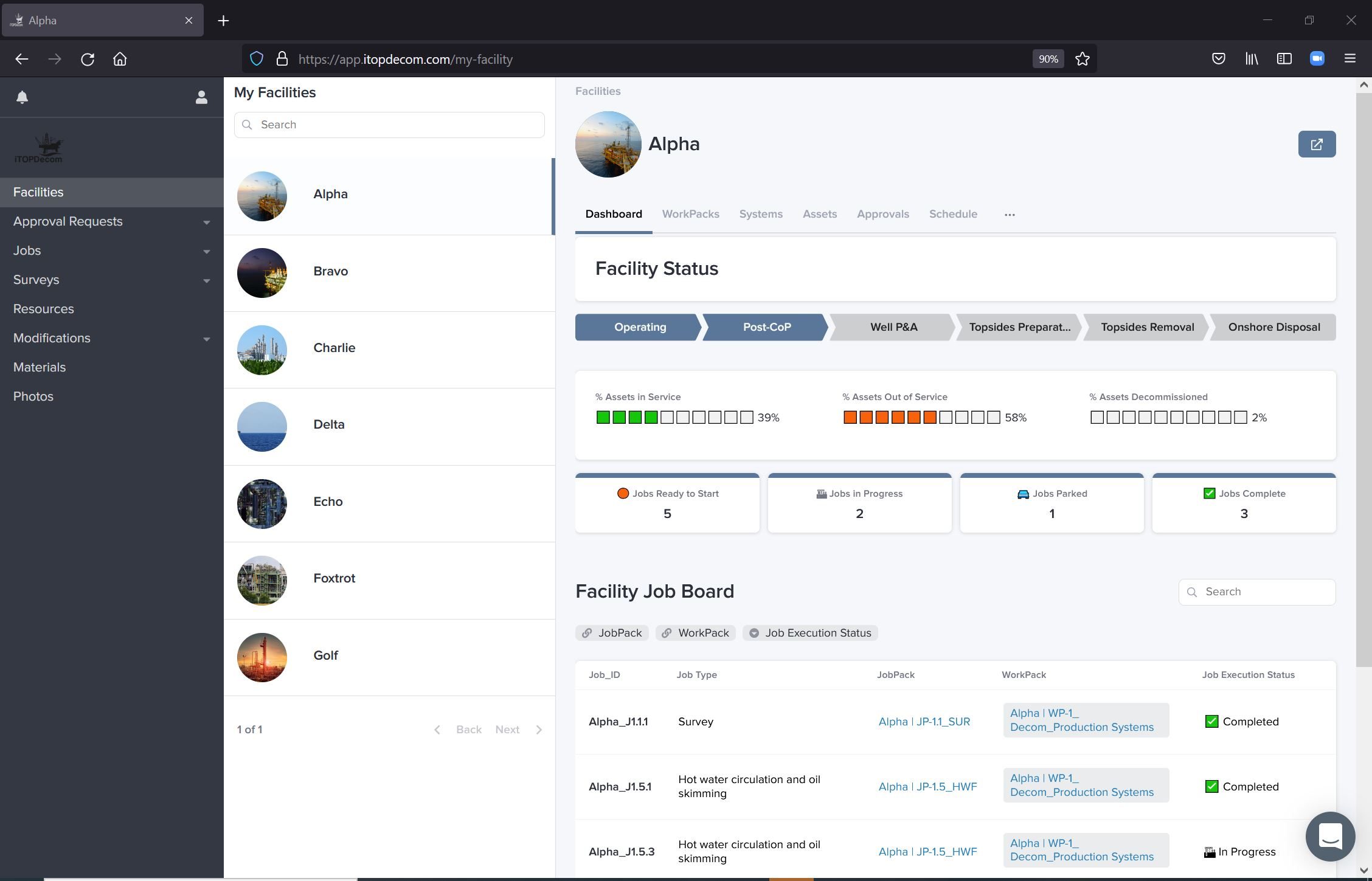

iTopDecom is a fully digital work planning, execution, and completions tracking tool used by offshore oil and gas decommissioning teams.

Designed by operations personnel, iTopDecom helps your offshore and onshore teams work together seamlessly and pull in the same direction.

Develop detailed schedules to set-out work sequences and identify the critical path for the full program of work ahead.

Create fully-digital job plans/workpacks in a collaborative workspace, with relationships between information mapped out.

Visualise the up-to-date status of jobs and assets on Kanban Boards and other intuitive user interfaces.

iTopDecom combines the functionality and power of multiple discrete tools into one easily accessible online/web-based platform.

Capture data in one place in a rules-based database repository rather than disparate digital and/or paper-based files.

Avoid the spin and actually join the digital revolution to rebel against the "business-as-usual" way of doing work.

A typical offshore oil and gas platform being decommissioned can be up to 50 years old, and comprises numerous assets, vessels, pipes, cables, and structural elements which need to be interacted with to prepare the platform for lift/module separation and return onshore.

The scale and complexity of the work involved is typically beyond the capability of base-business offshore operations and maintenance crews, and needs to be staged in a systematic and comprehensive way, considering the numerous interdependencies between systems as they are progressively shut-in and made safe.

Some users attempt to use existing completions management tools or numerous interlinked spreadsheets to manage this process. As these tools are typically not designed with decommissioning in mind, they invariably result in significant additional personnel effort and cost to the project, along with data integrity risks and poor traceability of activities.

iTopDecom’s bespoke and robust design approach provides the end user with confidence that they can safely and effectively manage the various decommissioning activities throughout an entire campaign, which may involve numerous platforms across a timeline that may extend up to or beyond a decade.

Decommissioning offshore platforms presents an opportunity to use digital technology to engineer down and clean up topsides (i.e., like untying an impossibly tangled knot) with an insightful and intelligent approach that renders the perceived constraints moot.

Powering iTopDecom is an enterprise grade, mission critical relational database with built in scripts, automations and workflows designed to solve these challenges.

Every asset is accounted for and categorised by a system, service, type, location etc. with customisable “make safe” rules applied to each asset, based on category, to determine the appropriate tasks required (e.g., survey, isolate, drain, flush, clean, purge, vent, open to atmosphere, etc.).

Assets are linked into the most appropriate jobs which then address these minimum make-safe requirements through an engineered design process. When jobs are approved complete, the status of the related assets can be changed to “decommissioned” and then approved to this state. Piping and tubing crossing module boundaries can be identified and separated safely, lifting points installed, etc.